University of Akron 55th Tire Mechanics Short Course

Deutsche Messe, Hannover, Germany, March 3, 4, 5 & 6, 2025

The 55th Tire Mechanics Short Course will be held concurrently with Tire Technology Expo 2025 in Hannover, Germany, on March 3-6, 2025.

This four-day educational and developmental course will provide engineers and scientists with an in-depth, intense study of the latest developments surrounding tire engineering. The course is designed for practicing engineers, chemists and scientists who are concerned with tires and vehicles and who have an engineering or science background at the Bachelor of Science level.

The basic and practical aspects of the mechanics of pneumatic tires will be introduced by internationally renowned experts in tire mechanics. Extensive, detailed course notes prepared by each instructor will be provided for all participants, along with a 700-page e-book, ‘The Pneumatic Tire’, edited by Professors Gent and Walter. Those who complete this course will receive a certificate from the University of Akron.

*COURSE FEE: €1,950 plus German VAT

Program Schedule

This Course takes place in the Sydney room

Monday, March 3, 2025

09:00 – 09:30

Welcome and introduction

Dr Xiaosheng Gao

Department of Mechanical Engineering, College of Engineering and Polymer Science

The University of Akron, Akron, OH, USA

09:30 – 16:30 (Complimentary lunch 12:00-13:00)

Tire components, tire compounds and tire materials

Dr Annette Lechtenböhmer

Goodyear Innovation Center, Luxembourg (retired); associate editor, Tire Science and Technology Journal

This lecture gives an overview of the tire components, the demands on their compounds and the use of materials in these compounds. It attempts to make the connection between the role of components in a tire, the compound requirements of these components and the raw materials and cure which results in the desired compound properties. The lecture wants to close the loop between the raw materials and reinforcements used, the compound properties, tire preparation and cure, and final tire properties. The lecture will cover:

- A short introduction

- Components of a tire and demands

- Tire compounds and their materials, including polymers, fillers, additives, sulfur and curatives

- Tire structures and composites, textile cords, wire, carcasses, beads, and belts

- Processing, including mixing, calendaring, and extrusion

- Tire building

Tuesday, March 4, 2025

08:30 – 16:00 (Complimentary lunch 12:00-13:30)

The tire as a vehicle component

Dr Gerald Potts

GRP Consulting, Akron, OH, USA

Dr James Cuttino, Presenter

Yokohama Corporation of North America, Cornelius, NC, USA

Today’s pneumatic tire must serve four functions: (1) support a moving load; (2) generate steering forces; (3) generate driving and braking forces; and (4) provide isolation from road irregularities. In examining the complex mechanisms involved in satisfying the four requirements, participants will study the tire’s importance in determining overall vehicle performance; for no matter what level of complexity is designed into a vehicle, its only communication with the road is through its tires, which must be tough and strong, yet flexible. The following topics will be covered:

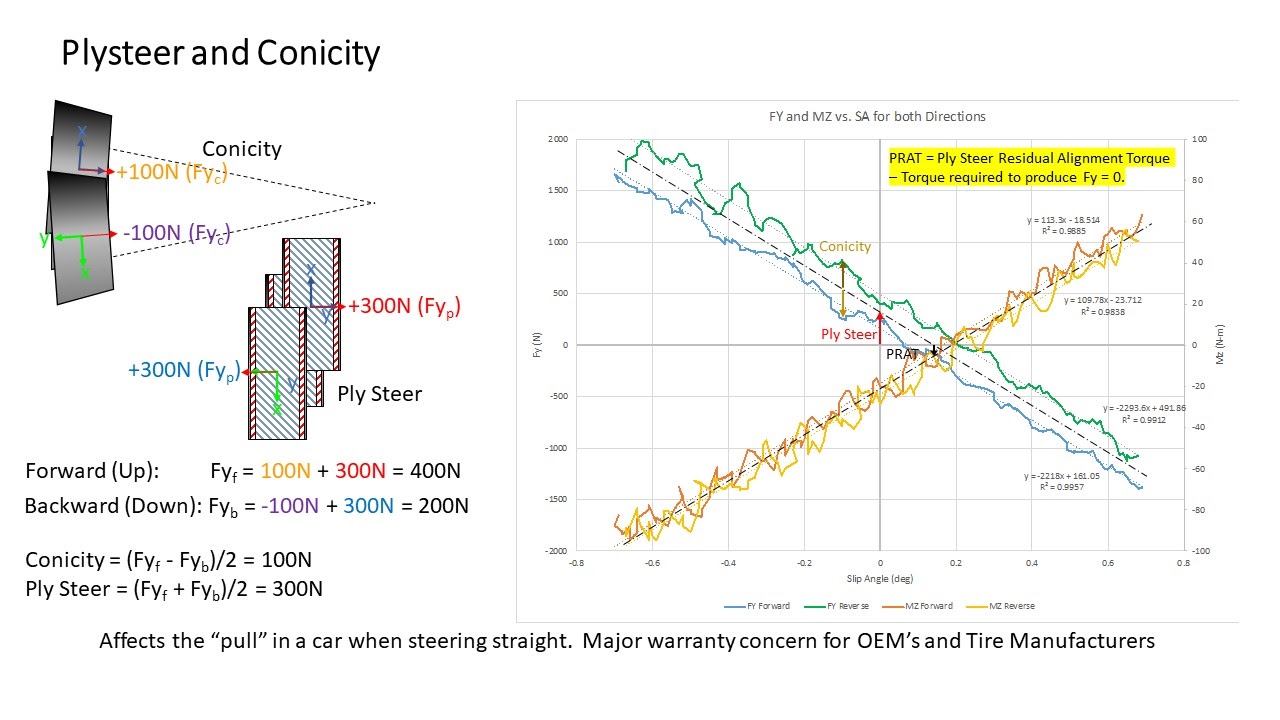

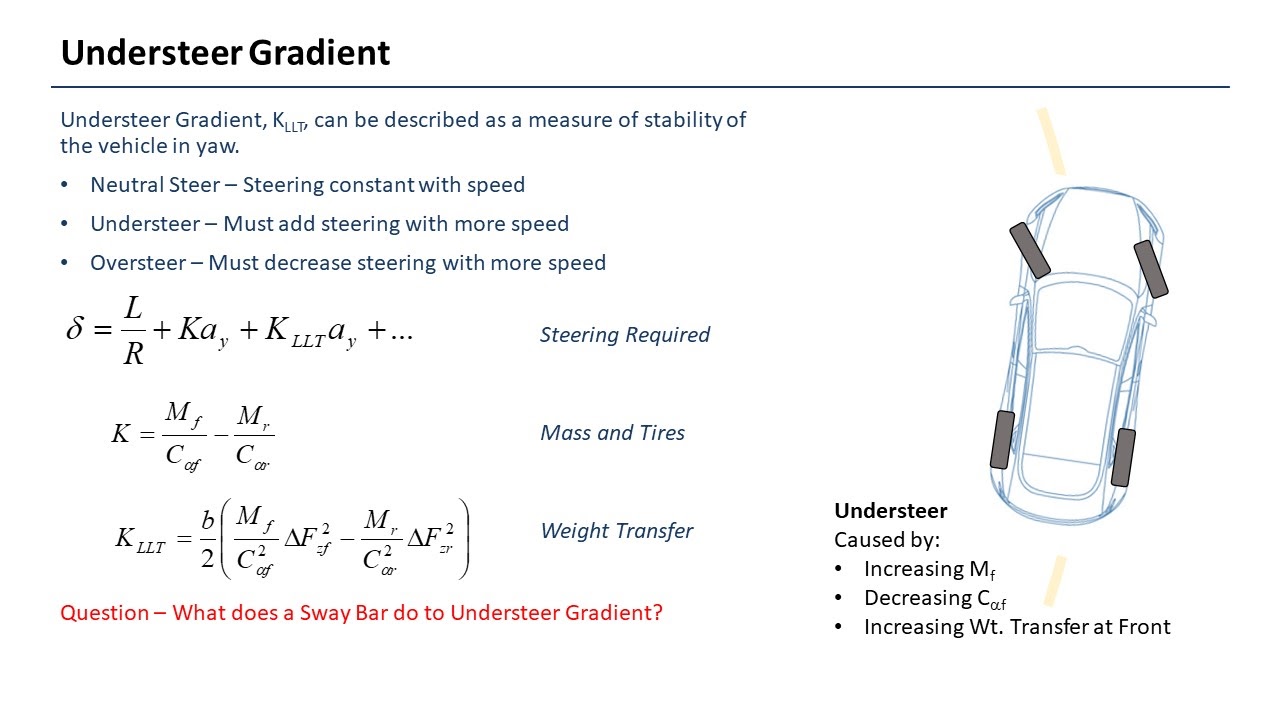

- Mechanics of force generation in the contact patch

- Tire performance (cornering and traction)

- The tire and vehicle dynamics

- Tire testing

- Brief overview of tire modelling

16:00 – 17:00 Visit to the exhibition

Wednesday, March 5, 2025

08:30 – 16:00 (Complimentary lunch 12:00-13:30)

Impact of rubber and reinforcement properties on tire footprint mechanics

Dr Mahmoud Assaad

Global tire performance prediction, computational mechanics

The Goodyear Tire & Rubber Co., Akron, OH, USA (retired)

The viscoelastic behavior of the rubber compounds and the reinforcing cords influences the stability of the tire footprint shape. Additional physical properties such as the strain dependency of both constituents and their thermal stability contribute to the contact pressure distribution. The resultant tire forces and moments transmitted to the vehicle are measured using tri-axial force pin transducers or pressure-sensitive mats. The interaction between the materials’ behavior and the tire global response controls the mechanics of tire readability and wear characteristics. The following topics will be discussed:

- Mechanical properties of rubber

- Elasticity and viscoelasticity

- Strength of rubber compound

- Payne and Mullins effects

- Energy dissipation

- Strain energy release rate

- Neural network (feed forward-back propagation) based constitutive model for rubber material

- Fibers and cords: load displacement, creep, stress relaxation and shrinkage

Impact of steel wires and polymeric cords on tire performance, reinforcement adhesive coatings and processing - Tire transient force and moment response to slip angle sweep

- Footprint characteristics

- F&M measurement

- Cornering stiffness

- Small-medium-large slip angle regimes

- Tire applications:

- How tires age and how to measure aging in tires

- Tire electric resistance

- Tire pressure loss over time – impact of liner material and thickness

- Tire post-cure inflation

- Tire digital twin technology

- Monitoring the health of tires using continuum damage mechanics (CDM)

16:00 – 18:00 Visit to the exhibition

Thursday, March 6, 2025

08:15 – 15:15 (Complimentary lunch 12:00-13:00)

Virtual tire modelling for improved performance

Dr Ronald Kennedy

Center for Tire Research,

The University of Akron and Virginia Tech, Blacksburg, VA, USA (retired)

associate editor of Tire Science and Technology Journal

Simulations are increasingly being used in companies’ virtual design processes to develop a tire more effectively and efficiently with desired performance attributes. These simulation methods run the gamut from simple empirical or analytical models to highly detailed finite element models. These increasing levels of modelling will be described along with examples, with extended focus on the finite element modelling method. Various finite element modelling techniques will be shown as part of the tire performance simulation examples. The lecture will cover:

- Tire load transfer, cord force and tire shape mechanics and model representations

- Review of tire performance modelling methods of increasing complexity, with examples

- Empirical

- Analytical

- Physically based numerical

- Brief introduction to tire finite element analysis (FEA)

- Application of FEA to tire performance prediction

- Tire/road contact and forces (static, rolling, cornering)

- Rolling resistance

- Tread wear

- Durability

- Hydroplaning

15:15 – 15:45

Course evaluations and distribution of certificates

Dr Xiaosheng Gao,

Department of Mechanical Engineering

The University of Akron, Akron, OH, USA

For course information, please contact:

Dr Xiaosheng Gao

Department of Mechanical Engineering

College of Engineering and Polymer Science

The University of Akron

Akron, OH 44325-3903, USA

Tel: +1 330 972 2415

xgao@uakron.edu

For registration information, please contact:

Tim Sandford

Conference director, UKi Media & Events

Parsonage House, Parsonage Square,

Dorking, Surrey, RH4 1UP, UK

Tel: +44 1306 743744

Fax: +44 1306 877411

tim.sandford@ukimediaevents.com