- 3D laser surface texturing

- Acoustic testing systems and components

- Adhesion resins

- Anti-tacks

- Automated systems and technologies

- Bead lines

- Bias and ply cutter technology

- Bonding agents

- Carbon black

- Cast-iron rolls

- Chemical dosing systems

- Clamping and palletization technology

- CNC milling machines

- Coating resins

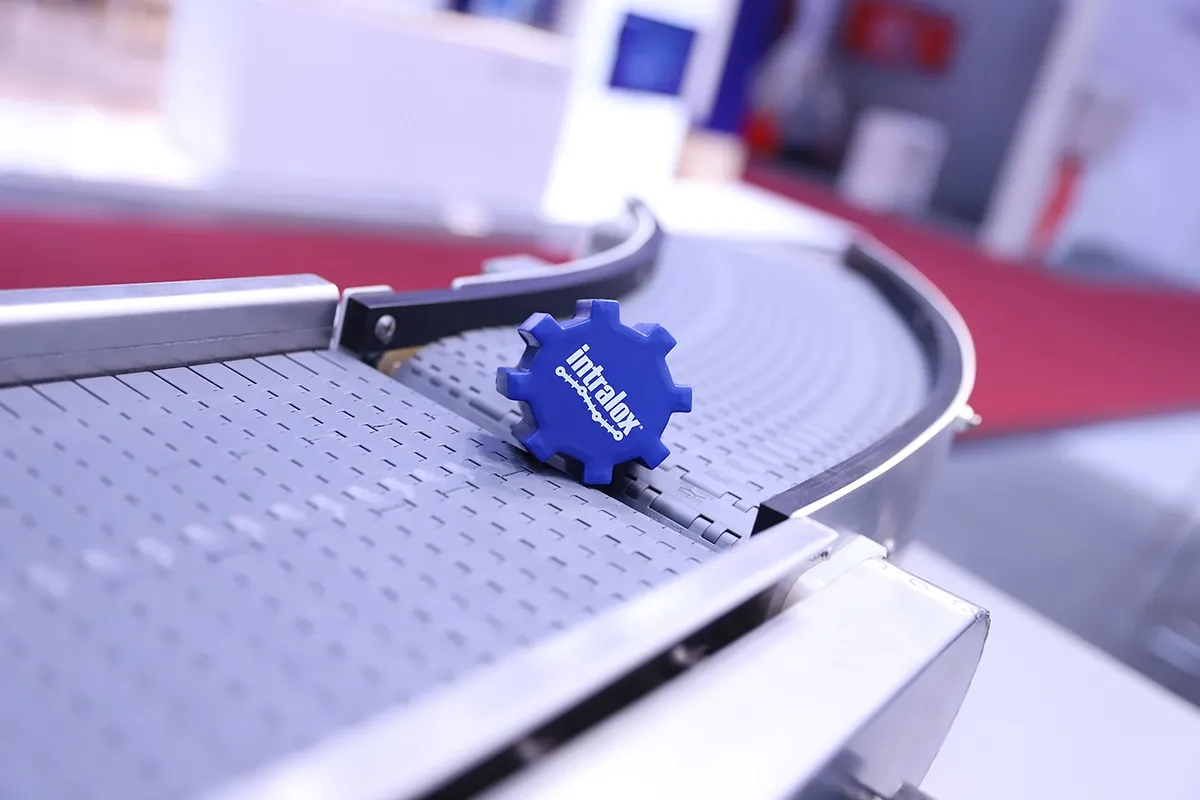

- Conveyor belting

- Cooling systems and heat carriers

- Curing systems and technologies

- Customized storage solutions

- Cutting technology

- Data acquisition

- Dynamic mechanical analyzers

- Elastomer characterization systems

- Electrical drives

- Engineering services

- Extruder head instrumentation

- Extruders and extrusion technology

- Pressure distribution measurement

- Process oils

- Profile scanning systems

- Reinforcing materials

- Release chemistry

- Research facilities and testing

- Factory management

- Gantry robots

- Green tire technology

- Handling automation solutions

- Homologation services

- Hydraulic systems

- In-line quality measurement systems

- Labeling systems

- Laser systems and components

- Liquid dosing systems

- Logistics solutions

- Marking systems

- Materials

- Measurement technologies

- Metal printing systems

- Mill room solutions

- Motion control components

- Natural rubber

- RFID, tracking and identification labeling

- Rubber calenders

- Rubber mixing technology

- Rubber process additives

- Slitting, rewinding and spooling solutions

- Smart tires

- Specialty chemicals

- Synthetic rubber

- Tension control instrumentation

- Tire building machine technologies

- Tire cord systems

- Tire design and simulation software

- Tire lifecycle monitoring solutions

- Tire mold technology

- Tire sipes

- Tire uniformity geometry and balancing

- Tire recycling

- TPMS reading solutions

- Valve technology

- Weaving systems

- Web guiding

- X-ray inspection